A COMPLETE STEAM SOLUTION

Custom-designed steam systems to enhance safety and efficiency for your industrial and commercial operations worldwide.

WHO WE ARE

We are specialists in the supply, installation, and ongoing support of high-quality steam boiler systems for both industrial and commercial applications worldwide.

Based in the UK with a truly global reach, we deliver robust, efficient, and reliable steam solutions tailored to the needs of diverse sectors—including manufacturing, energy, food, brewing and distilling, processing, petrochemicals, textiles, and large-scale commercial facilities.

Our approach goes far beyond supplying equipment. We offer a complete, end-to-end service: from expert consultation and custom system specification to seamless logistics, professional installation, commissioning, operator training, and comprehensive aftercare.

WHAT WE DO

Explore our comprehensive range of steam boiler systems and services designed to enhance efficiency and reliability in your operations.

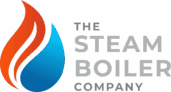

BAHR’12

High Pressure Flame Reversal Steam Generator

Overview:

The BAHR’12 series is a high-pressure, wet-bottom, flame inversion steam generator for outputs of 300–6000 kg/h, with standard pressure up to 12 bar and efficiency up to 96% (with economizer). Certified to PED 2014/68/EU and EN 12953-3:2016.

Key Features:

High-efficiency flame inversion design for low emissions

Fully automatic operation with comprehensive safety features

Optional integrated or external economizer for higher efficiency

Service walkway and easy maintenance access

Standard Equipment:

Steam and safety valves, level indicators, pressure and safety switches

Automatic water feed pump, moisture separator, manual blowdown

IP55 control panel, 400V, 3-phase

Options: second feed pump, economizer, filters, TDS, 24/72-hour kits

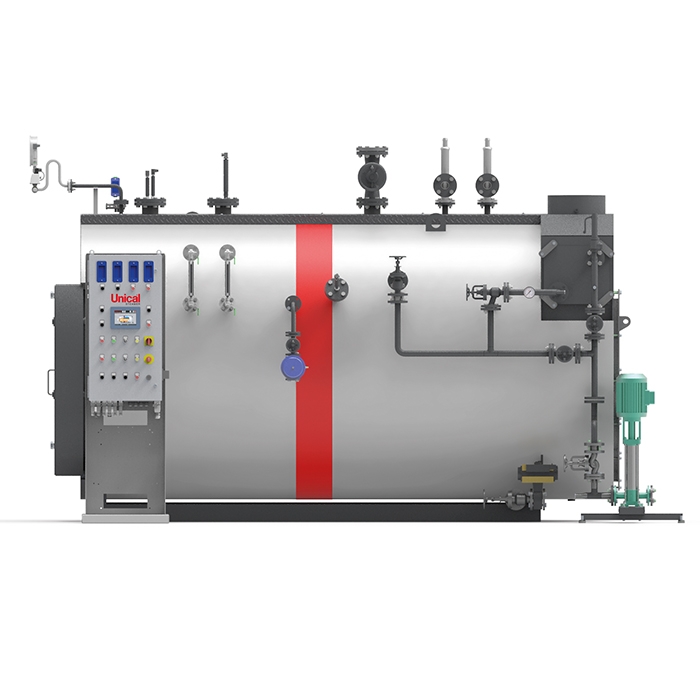

BAHR’12 3G

High Pressure Three-Pass Steam Generator

Overview:

BAHR’12 3G offers high-pressure steam generation (up to 12 bar; higher on request) with outputs from 800–4000 kg/h and three effective smoke passes for maximum heat transfer and up to 96% efficiency. CE PED marked, EN12953-3:2016 compliant.

Key Features:

Three-pass horizontal design for high steam quality

Large evaporating chamber and efficient heat exchange

Automatic operation and robust safety systems

Low NOx emissions when equipped with Low NOx burner

Standard Equipment:

Steam and safety valves, level indicators, pressure and safety switches

Water feed pump, moisture separator, quick opening drain

Service walkway, manholes for inspection

IP55 control panel, 400V, 3-phase

Options: economizer, filters, second pump, 24/72-hour kits

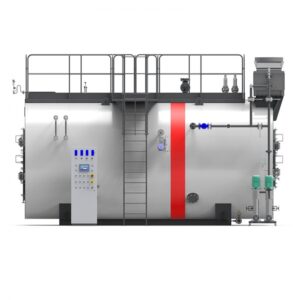

TRYPASS’

High Capacity Three-Pass Steam Generator

Overview:

TRYPASS’ series offers high-pressure, monobloc steam generation with three effective smoke passes, designed for outputs of 2000–22000 kg/h and pressures up to 12 bar (higher on request), achieving up to 96% efficiency (EC version). CE PED marked and EN12953-3:2016 compliant.

Key Features:

Three-pass horizontal design with wet bottom for maximum performance

Designed for high steam output and long service life

Fully automatic controls and comprehensive safety systems

Service walkways, easy access for inspection

Standard Equipment:

Steam and safety valves, level indicators, pressure and safety switches

Water feed pump, moisture separator, quick opening drain

Control panel IP54, 400V, 3-phase

Options: external economizer, second pump, filters, ladders, 24/72-hour kits

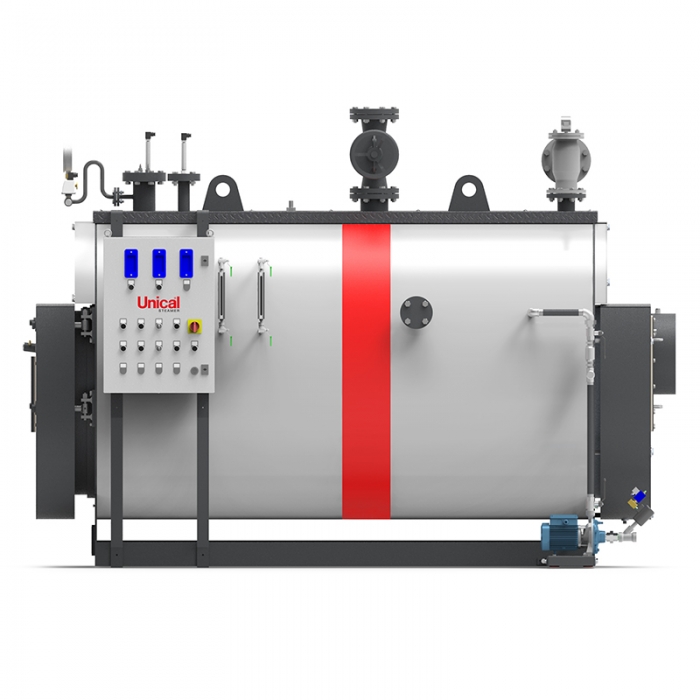

BAHR’UNO

Three-Pass Low Pressure Steam Generator

Overview:

The BAHR’UNO is a packaged, low-pressure, three-pass, reverse flame steam generator with wet back, suitable for steam outputs from 140–4000 kg/h at pressures up to 0.98 bar and efficiency up to 97%. Conforms to PED 2014/68/EU and EN12953-3:2016.

Key Features:

Robust, high-efficiency three-pass design

Fully automatic operation with advanced safety controls

Easily accessible for inspection and cleaning

High-quality construction for long service life

Standard Equipment:

Steam and safety valves, level indicators, pressure and safety switches

Water feed pump, moisture separator, quick-opening drain

IP55 control panel, 400V, 3-phase

Options: economizer, second pump, water filters, TDS, 24/72-hour kits

BAHR’UNO CB

Low Pressure Flame Reversal Steam Generator

Overview:

The BAHR’UNO CB series are flame inversion, wet-bottom, low-pressure steam generators (max 0.98 bar), with steam output from 100–1000 kg/h and efficiency from 91% to 95%. Each unit is CE PED marked and built to EN12953-3:2016 standards.

Key Features:

Cylindrical steel body, insulated for safety and efficiency

Advanced combustion chamber for efficient heat transfer

User-friendly access for inspection and maintenance

Automatic control with robust safety systems

Standard Equipment:

Steam and safety valves, level indicators, pressure gauge

Automatic water feed pump and level controls

Manual sludge drain and moisture separator

IP55 control panel, 400V, 3-phase

Complete documentation

Options: second feed pump, inlet filters, TDS kit, 24/72-hour unsupervised operation

EL7

Instantaneous Electric Steam Generator

Overview:

The EL7 is a compact, high-efficiency (up to 99%) electric steam generator designed for working pressures up to 5.0 bar (8.5 bar on request), with steam production from 20 to 250 kg/h (15–180 kW). CE marked to PED 2014/68/EU, it offers easy installation with just four connections: electric supply, steam outlet, drain, and water inlet. The vertical design ensures a minimal footprint.

Key Features:

Modular configuration with multiple pressure vessels and electric resistors for precise steam and power modulation

Automatic operation via intuitive control panel

Direct water feed from mains or condensate tank

Simple installation and maintenance

Standard Equipment:

Steam and safety valves, pressure gauge, level indicator

Automatic water level control and feed pump

Manual bottom blowdown valve

230/400V control panel, 3-phase, 50/60 Hz

Complete documentation

StEM

Modular Electric Steam Generator

Overview:

The StEM series offers instant, fully automatic electric steam generation, achieving up to 99% efficiency at operating pressures up to 8.0 bar. With models producing 40–320 kg/h (30–240 kW), StEM units are CE marked to PED 2014/68/EU. Modular construction allows flexible, space-saving installations.

Key Features:

Scalable output via multiple interconnected modules

Quick and straightforward installation with four main connections

Intuitive Ufly P panel interface for automated management

Compact, modular footprint

Standard Equipment:

Individual steam and safety valves, pressure gauge, level indicator per module

Automatic water level control, feed pump, and discharge/ purge unit

400V control panel, 3-phase + neutral

Full documentation

Optional: condensate tank, single supply kits, steam manifolds

Steam Boiler Accessories

Enhance your steam system’s performance and safety with our range of high-quality, factory-tested accessories. Find solutions for condensate recovery, level control, water treatment, and automation.

1. Condensate Recovery & Water Handling

Condensate Return Tanks (200 L) – Efficiently reclaim condensate to save energy and water, complete with level control and pump systems.

Feed Water Pumps – Rugged centrifugal pumps for consistent boiler feed. Kits available for single or dual pump configurations.

Inlet Water Filters – Protect boilers from sediment and particulates with inline filtration kits.

2. Level Detection & Control

Capacitive / Reflection Level Indicators – High-visibility, safe level detection with isolation valves and drain cocks.

SIL‑2 / PED Safety Level Switches – Certified high- and low-level protection compliant with SIL-2 and PED standards.

TDS Monitoring & Blowdown Kits – Maintain water quality and prevent scale buildup with total dissolved solids (TDS) probes and automated periodic blowdown.

3. Valves & Blowdown Systems

Steam Outlet & Main Valves – High-grade shut-off and flow valves compatible with all standard boilers.

Manual Bottom Blowdown Valve – Robust valves for efficient sludge and sediment removal.

Automatic Bottom Blowdown Kits – Hands-free operation for continuous sludge management; available for select boiler models.

4. Economizers & Heat Recovery

Integrated / External Economizers – Boost boiler efficiency (up to +6%) by preheating feed water with residual flue gases.

Cascade Manifolds – Simplify piping for multi-boiler setups with common steam outlets and condensate return systems.

Burner Plates – Customizable plates to suit different burner types for optimal combustion performance.

5. Automation & Remote Monitoring Kits

24‑Hour / 72‑Hour Exemption Kits – Upgrade panels to meet “unattended” operation standards for 24 h or 72 h continuous operation.

Cascade Control Kits – Enable master/slave operation for boilers in modular installations using IML panels.

Communication Interfaces (Modbus, Profinet, RS‑485) – Extend automation by integrating boilers into building management systems (BMS).

VNC / VPN Remote Access – Monitor and control boilers remotely via secure digital connections.

6. Additional Options

Second Feed Pump Kit – Install a backup for uninterrupted water supply.

Maximum-Level Safety Kits – Ensures high-level protection beyond standard probes.

Burner Drilling Service – Custom drilling to match your specific burner configuration.

Inspection Ports & Service Walkways – Improve accessibility for maintenance on larger, high-capacity units.

Electric Control Panels

Overview:

A complete range of electric control panels for steam generators, from simple electromechanical designs to advanced PLC-based touchscreen systems. Each panel offers essential boiler automation, safety, and expandability to suit your installation.

| Feature | BASIC | BASIC-P | IML (Industrial Multi Logic) | IML FT (Full Touch) |

|---|---|---|---|---|

| Burner Regulation | 1/2-stage | 1/2-stage | 1/2/3-stage or Modulating | 1/2-stage or Modulating |

| Water Level Control | ON/OFF | ON/OFF | ON/OFF/Modulating | ON/OFF/Modulating |

| Safety Level Switches | 2 SIL-2 | 2 SIL-2 or PED | 2 PED | 2 PED |

| Display/Interface | LED/Lamps | LED/Lamps | 10" Touchscreen | 10" Touchscreen |

| Control Logic | Relay/Electromech | Relay/Electromech | PLC-Based | PLC-Based |

| Expandable/Optional Kits | Yes | Yes | Yes | Yes |

| Manual Operation | Yes | Yes | Yes (except burner) | Yes (except burner) |

| Communication | No | No | Modbus TCP/IP, Profinet | Modbus RS485 |

| Remote Supervision | No | No | VNC/VPN | VNC/VPN |

| Multi-Boiler Cascade Control | No | No | Yes | Future Feature |

| Protection Degree | IP55 | IP55 | IP54 | IP54 |

| Panel Versions | Single | Single | Box or Floor Standing | BASIC/24hr/72hr/Industry 4.0 |

| Power Supply | 400V 3Ph+N 50Hz | 400V 3Ph+N 50Hz | 400V 3Ph+N 50Hz | 400V 3Ph+N 50Hz |

WHY US?

Industry Expertise

With decades of experience supplying, installing, and servicing industrial and commercial steam boilers worldwide, our team understands what it takes to keep your operation running safely and efficiently.

Complete Solutions

We provide more than just products – we deliver end-to-end solutions. From consultation and system design, to installation, commissioning, and ongoing support, we’re with you every step of the way.

Quality & Compliance

All our systems meet stringent international and UK standards, including CE and PED certification. You can trust us for reliable, efficient, and compliant steam solutions for any sector.

Responsive Support

Our engineers are available for technical advice and rapid-response callouts, ensuring minimal downtime and complete peace of mind.

Global Reach, Local Service

Based in the UK and operating worldwide, we combine global capability with local attention and accountability.

Flexible, Customer-Focused Approach

Every client’s needs are different. We tailor our recommendations and support to your specific site, process, and budget—whether you’re upgrading, expanding, or installing new equipment.

CONTACT US

Birchwood

Warrington

Cheshire

United Kingdom